As a facility engineer, director/manager, electrical engineer, or electrical supervisor, do you need to consider natural ester dielectric fluid in your transformers? Why would you even need to make this consideration given mineral oil has been in your transformers for years? Well, that decision might be influenced by your insurance provider and the fact that past practices are not always right for today’s applications.

As one of the largest purchasers of FR3 fluid natural ester dielectric fluid, Sunbelt Solomon has seen insurance companies such as FM Global, Zurich, AIG, Travelers and others increase their awareness of fire prevention when it comes to existing transformer installations.

Specifically, insurance providers are taking a second look at:

- Mineral oil-filled transformers located indoors

- transformers in close proximity to buildings or each other

- the type of oil containment

- where there might be risk of spills into the environment (such as installations near waterways or storm water drainage systems)

These situations can be trouble should you experience a catastrophic failure or leak, unless you have preventive measures in place including Natural Ester [FR3 fluid] filled transformers, or transformers retrofilled with a natural ester fluid such as FR3 fluid.

The picture above is from a recent FR3 fluid retrofill (replacing mineral oil with FR3 fluid) conducted by SUNBELT SOLOMON SOLUTIONS for a nationwide Petrochemical company. The FR3 fluid retrofill of two (2) 20MVA transformers eliminated the need for very expensive blast walls between transformers and also provided several additional benefits.

So what are the benefits of natural esters such as FR3 fluid? How about:

- Reduced fire risk – zero reported fires

- Improved environmental footprint

- Increased transformer life expectance

- Optimized transformer performance

- Cost Implications

Reduced Fire Risk

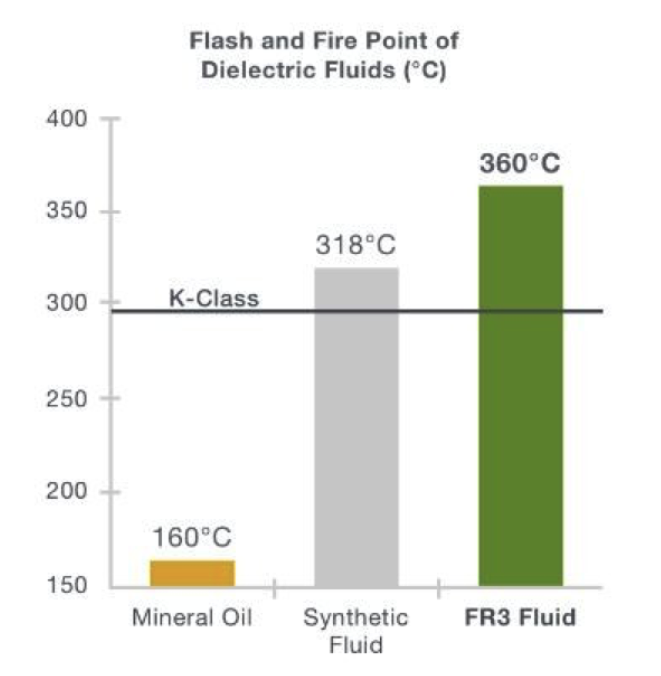

OSHA defines a flammable liquid as “any liquid having a flash point below 93°C”. This would apply to mineral oil; however, ester-based fluids such as FR3 fluid are much less flammable than mineral oil, it is also “non-propagating” per the National Electrical Safety Code.

FR3 fluid is a K-class fluid with extremely high flash and fire points [330℃ and 360℃, respectively] compared to mineral oil [155℃ and 160℃]. It can drastically reduce the need for containment and separation between transformers, other equipment, and structures.

The use of FR3 fluid reduces the requirements for expensive options–such as secondary containment, blast walls, and fire suppression systems–and allows equipment to remain indoors or in close proximity to buildings, streams, and waterways. NEC standards permit the instillation of FR3-fluid-filled transformers indoors without fire-suppression sprinkler systems or vaults, and with minimum wall clearance of only 3 feet.

A note about retrofilling mineral oil filled transformers. As natural ester fluids have a fire point of 360°C, the fire point does not drop significantly during retrofills unless there is about 7.5% residual mineral oil left in the transformer windings, internals and gaskets, it does not drop out of a K-class fluid until approximately 8% residual mineral oil is left in the system (Cargill, 2018). The contractor should use the measurement of the fire point of the dielectric fluid after the retrofill as a measure of the success of the retrofill. A successful retrofill should result in a fire point greater than 300°C. Unsuccessful retrofills should be evaluated for a new retrofill. A typical retrofill would include draining, flushing and repeating prior to final fill. A properly retrofilled transformer will benefit from the flawless fire safety history associated with FR3 fluid.

Improved Environmental Footprint

FR3 fluid is a natural ester fluid derived from vegetable oils. It is an eco-friendly fluid, designated as biodegradable by the Environmental Protection Agency, offering a non-toxic biodegradable alternative that is free of petroleum, halogens, sulfurs, and silicones.

The environmental impact of a spill of FR3 fluid would be minimal and remediation costs lower since the fluid is higher in viscosity, biodegradable, non-toxic, and non-hazardous in soil or water. Per EPA SPCC Bulletin 1724E302, secondary containment could be a simple earthen berm and Biodegradation is a legitimate water/soil remediation tool. (Cargill, 2016)

FR3 fluid has excellent miscibility and compatibility with conventional mineral oil and high temperature hydrocarbon fluids (i.e. R-Temp® fluid). Important Note – FR3 fluid is not miscible with silicone and should not be applied in transformers previously containing silicone.

Increased Life Expectancy

Moisture and heat are a transformer’s two worst enemies. Moisture in dielectric fluid, such as mineral oil, can contribute to low dielectric strength and cause dielectric failure. Transformers produce water over time as part of their normal operation, a product of internal gases produced.

As a mineral-oil-filled transformer operates, internal temperatures increase and moisture migrates from the paper insulation into the fluid, returning back into the paper when the temperature reduces. Natural esters like FR3 fluid have a unique ability to draw out and retain this moisture at a rate of 10x more than mineral oil while maintaining dielectric strength. Natural ester fluids “dry out” a transformer’s insulation through a process called Hydrolisis, where the fluids absorb free water, capture it, and turn it into long-chain fatty acids, thus keeping the insulation dry.

Hydrolysis slows down the aging process of cellulose paper, increasing the longevity for transformers and other equipment. The high water saturation point of FR3 fluid can extend the life of an insulation system by five to eight times.

Optimized Transformer Performance

FR3 fluid’s ability to preserve cellulose paper insulation systems, even at elevated temperatures, allows for transformer designs up to 20℃ higher than standard mineral oil-filled units. This allows kVA ratings to be increased accordingly, improving overall performance and in cases eliminating the need to upgrade or replace units. Should a retrofill be performed and increased kVA is desired, higher temperature gaskets are required such as silicone or flouropolymer (Viton) composition. Should a transformer be in service for more than 20 years prior to a retrofill, it is highly suggested to replace all gaskets regardless. Transformers operated at higher temperatures should have all gaskets replaced after 10 years of operation.

Cost Implications

Taking a proactive approach to loss prevention and standardizing on natural ester fluids such as FR3 fluid is a step in the right direction to mitigating potential catastrophes while supporting the environment and communities. Mitigating potential catastrophes can also be directly proportional to lower insurance and liability costs.

The Federal Energy Regulatory Commission (FERC) has ruled that all costs associated with the conversion to natural ester fluids (fluid, labor, equipment) may be capitalized due to its proven benefits for the environment. This is a big financial plus that eliminates the need to increase or justify expenses as part of ongoing O&M Budgets.

The cost of natural and synthetic ester fluids should be a consideration compared to mineral oil. Natural ester fluid cost, based on volume, is approximately double the cost of mineral oil, and synthetic ester fluid is approximately double the cost of natural ester fluid.

In closing, Sunbelt Solomon recommends FR3 fluid retrofills:

- To reduce fire hazards associated with transformers in close proximity to buildings, and transformers located within buildings.

- For locations in environmentally sensitive locations near waterways and parks.

- For overall reliability of critical loads

- To assist with the removal of water from paper insulation

- For transformers loaded to nameplate ratings to gain additional capacity

- To extend the life expectancy of transformers